E-Beam and Optical Lithography

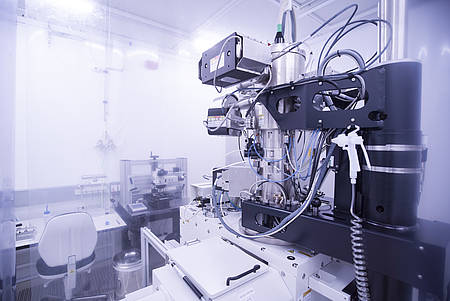

Electron Beam Lithography (EBL)

RAITH EBPG5150 EBL

The EBPG5150 electron beam lithography system is designed for high-resolution and high-accuracy patterning of devices on semiconductor wafers. Highly focused electron beams are used to draw circuit patterns on the nanometer scale onto semiconductor wafers coated with resists.

- High current density Thermal Field Emission gun for operation at 20-100 kV

- 155 mm platform

- Minimum feature size of less than 8 nm

- Rapid exposure with 50 or 100 MHz pattern generator

- Continuously variable large field size operation to 1 mm at all kVs

- GUI for ease of use operation for diverse “multi user environment”

- Thermal Field Emission (TFE) electron source

- Automatic dynamic off-axis focus, stigmation and distortion correction software

- Low noise 20-bit main field deflection

- Field size operation, variable up to 1mm by 1mm at all voltages

- Binocular microscope, X/Y stage and Laser Height sensor to pre-align wafers

- System control software suite “BEAMS” on fully integrated control PC.

User Support and Scientific Advice:

Salvatore Bagiante salvatore.bagiante@ist.ac.at

Juan Luis Aguilera juan.aguilera@ist.ac.at

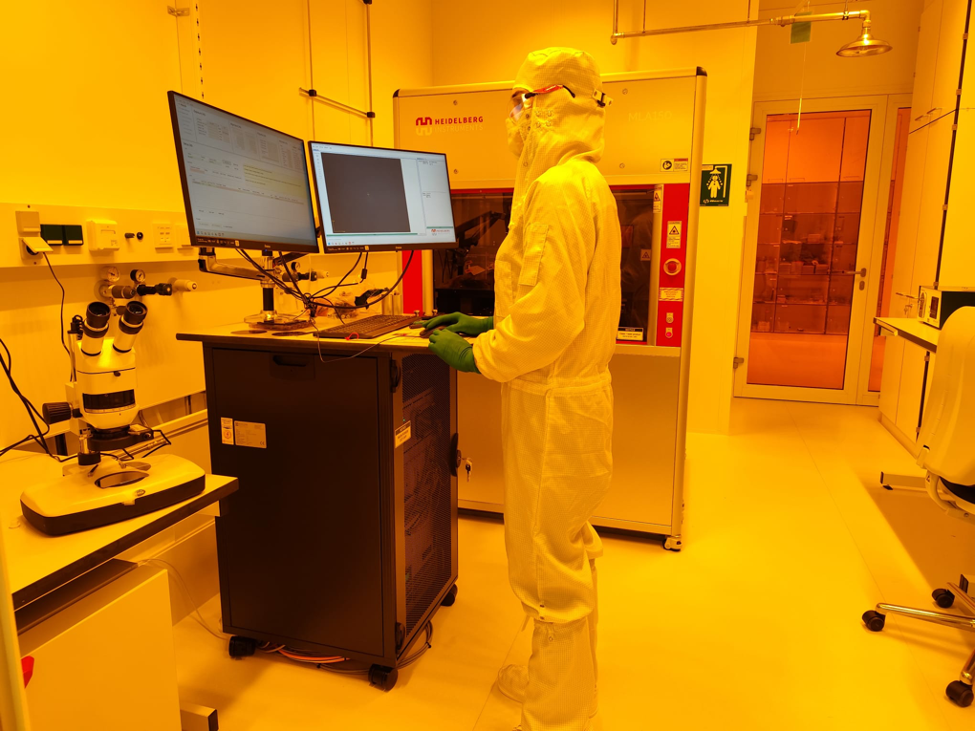

Maskless Lithography (MLA)

Heidelberg Instruments MLA 150

The MLA 150 is a high-speed, maskless direct-writing lithography system designed for accurate, and efficient patterning of photoresist-coated substrates. Its direct-write technology enhances performance and reduces operational costs by eliminating physical masks. A 375 nm exposure laser delivers sufficient energy to expose thick or less sensitive resists while maintaining excellent pattern accuracy, enabling the fabrication of features as small as 0.6 μm.

- Laser: 375 nm

- Feature size ≥ 0.6 μm

- Lines and spaces ≥ 0.8 μm

- Global 2nd layer alignment ≤ 0.5 μm

- Local 2nd layer alignment ≤ 0.25 μm

- Backside alignment ≤ 0.1 μm

- High aspect ratio mode for optimized sidewall profiles in thick resist

- Adjustable focus depth for improved pattern quality

- Wide range support of various substrate sizes

- Environmental chamber with controlled temperature and humidity

- Laminar airflow

User Support and Scientific Advice:

Carola Rando carola.rando@ist.ac.at

Juan Luis Aguilera juan.aguilera@ist.ac.at

Mask Aligner

EVG 610 Mask Aligner

The EVG 610 is a semi-automated system that can handle small substrate pieces and wafers up to 200 mm. The tool supports lithography processes, such as vacuum-, soft-, hard- and proximity exposure mode.

- Supports back side lithography and bond alignment processes when configured with bottom side microscopes

- Sub-micron exposure gap repeatability in proximity exposure mode

- Unmatched exposure light uniformity at wafer level, down to ± 1.5% for small substrate applications

- Windows based user interface

User Support and Scientific Advice:

Lubuna Shafeek lubuna.shafeek@ist.ac.at

Carola Rando carola.rando@ist.ac.at

Nasima Afsharimani nafshari@ista.ac.at