September 4, 2024

A Very “Clean Room”

Take a glimpse into ISTA’s Nanofabrication Facility

The Nanofabrication Facility (NFF) at the Institute of Science and Technology Austria (ISTA) processes materials at the nanoscale, helping research projects ranging from material science, and quantum computing to life sciences. Within specialized, nearly contamination-free rooms, scientists dressed in white overalls operate complex machines and microscopes. Take a tour with us to the hidden places of a research institute.

Austria, Klosterneuburg, ground floor of Lab Building West at ISTA. As you walk past laboratories and scientists, a huge safety door suddenly obstructs your path. Eventually, the door slowly opens, revealing a peculiar room. It could be straight out of a science fiction movie—perhaps a space station, maybe an outpost on Mars?

“Before you enter the dressing room, please cover your shoes and step on the sticky mat to clean the soles.” Matko Kandzija and Evgeniia Volobueva, two staff members of the Nanofabrication Facility (NFF), welcome you to the cleanroom. An automatic shoe cover dispenser wraps your feet with blue foil. The safety door beeps and closes automatically. This is as far as you get. Only authorized scientists and personnel are permitted to enter the cleanrooms.

The bunny suit

A cleanroom is not just clean, it is a meticulously controlled environment designed to minimize the presence of airborne particles, pollutants, and contaminants. The rules are very strict, even the smallest contamination can affect the functionality, or quality of products being developed within. A special air filter helps in this regard. “It is designed to capture particles, from dust to pollen to bacteria,” explains Salvatore Bagiante, manager of the Nanofabrication Facility (NFF) at the Institute of Science and Technology Austria (ISTA).

The primary source of contamination is the human body. When entering, scientists must wear special suits. Known as the bunny suit, this garment is made of materials that do not shed any particles. It has electrostatic dissipative properties to reduce static electricity that might attract particles. After each use, worn suits are cleaned and stored in a so-called hood. “It’s a wardrobe with a ventilation system with clean circulating air that removes all the particles that stick to the suits,” says Kandzija.

Constructing materials at the nanoscale

Kandzija and Volobueva guide you further into Lab Building West. A transparent glass wall now separates you from the cleanrooms. Inside, white bunny suits scurry around, working on machines. The NFF, which is part of ISTA’s Scientific Service Units, provides 450 m2 of cutting-edge laboratories. This facility combines various levels of cleanrooms, each distinguished by the maximum number of particles permitted per cubic meter of air, and several characterization laboratories.

“As the NFF staff, we’re helping PhD students, postdocs, and group leaders make their ideas become reality.” – Salvatore Bagiante

“As the NFF staff, we’re helping PhD students, postdocs, and group leaders make their ideas become reality,” explains Salvatore Bagiante. The NFF provides tools to fabricate devices on a nanoscale helping research projects ranging from material science to quantum computing to life sciences. These devices can be, for example, small electronics like microprocessors that are the building blocks for modern computers and smartphones. They can also be opto-mechanical devices—gadgets that combine mechanical parts with light, commonly used in sensors. Another example would be microfluidic devices—systems that mimic a conventional laboratory experiment on a microchip.

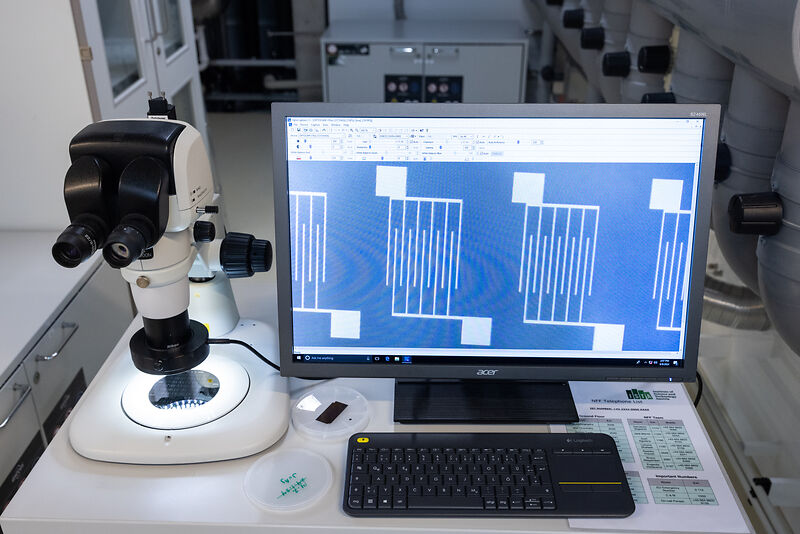

“A typical work day for our staff starts by checking the status of all the equipment and, if needed, restarting some of it or fixing the issues that happened out of business hours,” says Bagiante. “One of our most exciting tools is the electron beam lithography system, which allows the creation of detailed patterns on surfaces, 100 times smaller than a human hair,” he continues. It is an excellent tool for creating patterns on microchips. This lays down pathways that form the circuits that enable these nanostructures to be connected to the real world and measured with sophisticated electronics.

Another impressive tool that excites tech nerds is the high vacuum evaporator. It aids in adding thin layers of material to surfaces. Similarly, though on an even smaller scale, atomic layer deposition allows the formation of thin layers of materials (such as insulators and metals) by adding atomic layer by atomic layer on different substrates.

Supporting science

Circling the stringent cleanrooms, you continue to navigate through the narrow aisle to enter a room used for different other fabrication processes. Plastic curtains create a barrier to minimize contamination. Here you can find tools, such as a 3D nano printer, a microscope, two bonding machines and a PFIB xenon plasma-focus ion beam. The latter is not a Star-Trek-style rocket engine, scientists use it to cut, shape, or remove material from a solid surface, much like a high-tech sawmill. “It allows for super-fast milling of any material,” Bagiante adds excitedly. These minuscule slices of material can be then analyzed using sophisticated detectors directly within the system.

Of course, there is also an annual “spring cleaning” in a cleanroom. This thorough cleaning occurs once a year. Despite meticulous work, dirt inevitably accumulates. “It’s a multi-day process and requires good planning and coordination with research groups at ISTA,” explains Volobueva.

The close interaction between the NFF staff and scientists, as well as the opportunity to access the institute’s cleanroom at any time, are crucial for the realization and ultimately the success of many research projects.

Once more, “beep, beep,” chimes the automated door. It has remained open for too long and must be closed quickly. It is time to dispose of the blue shoe covers and return to the real world.